Let us help

Please complete the form below and our team will contact you as soon as possible.

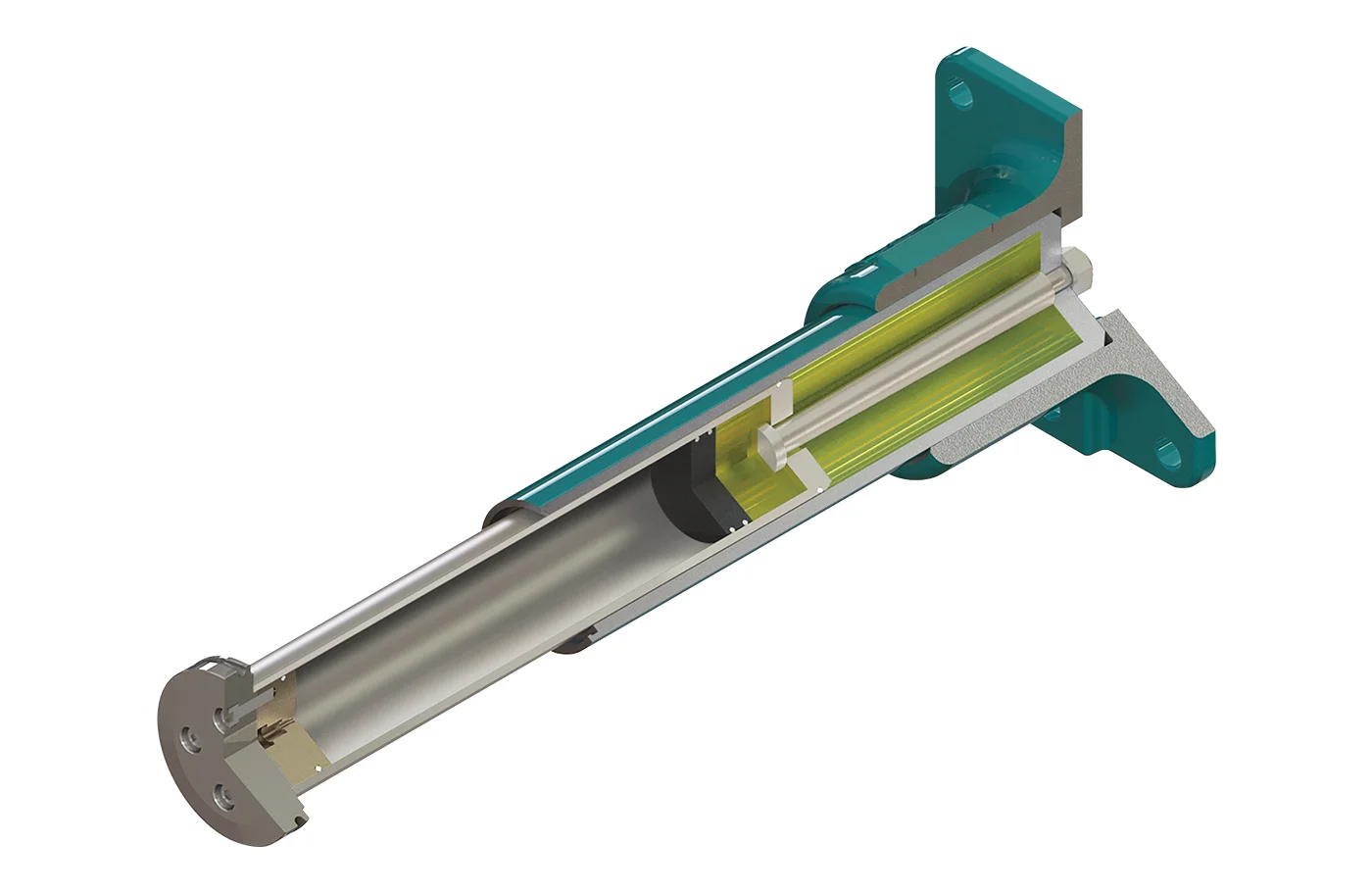

The illustration demonstrates the robust construction of the Oleo hydraulic unit. Upon impact, theplunger is driven into the cylinder, displacing oil through a metering orifice. This movement drivesthe separator piston and compresses the gas chamber. The compressed gas then acts on the oil viathe separator piston, generating a controlled recoil force that re-extends the unit after impact. Theamount of energy absorbed and dissipated is dependent on the closure velocity.

When the plunger enters the cylinder at high speed, the displaced oil is forced through the orifice atvery high velocity. This process increases the pressure within the oil chamber to a level thatoptimises the closure force of the unit. This optimisation ensures that impact energy is absorbedevenly throughout the plunger stroke, maintaining a consistent impact force. This capability isachieved through Oleo’s advanced metering designs, which progressively modify the flow area as theunit closes. Each metering profile is precisely calculated to provide optimal protection for rollingstock at defined impact speeds.

As a result, the Oleo hydraulic unit offers the distinctive advantage of performance characteristicsthat adapt to operational requirements. Most of the impact energy is absorbed within the unit itself,while the already low recoil force is further damped by the reverse flow of oil. This ensures thatminimal residual energy and recoil force are transmitted back to the impacting vehicle.

Please complete the form below and our team will contact you as soon as possible.